The fully planked platforms are to remain in place until the scaffold is dismantled.

#Exterior scaffold drawing pdf install

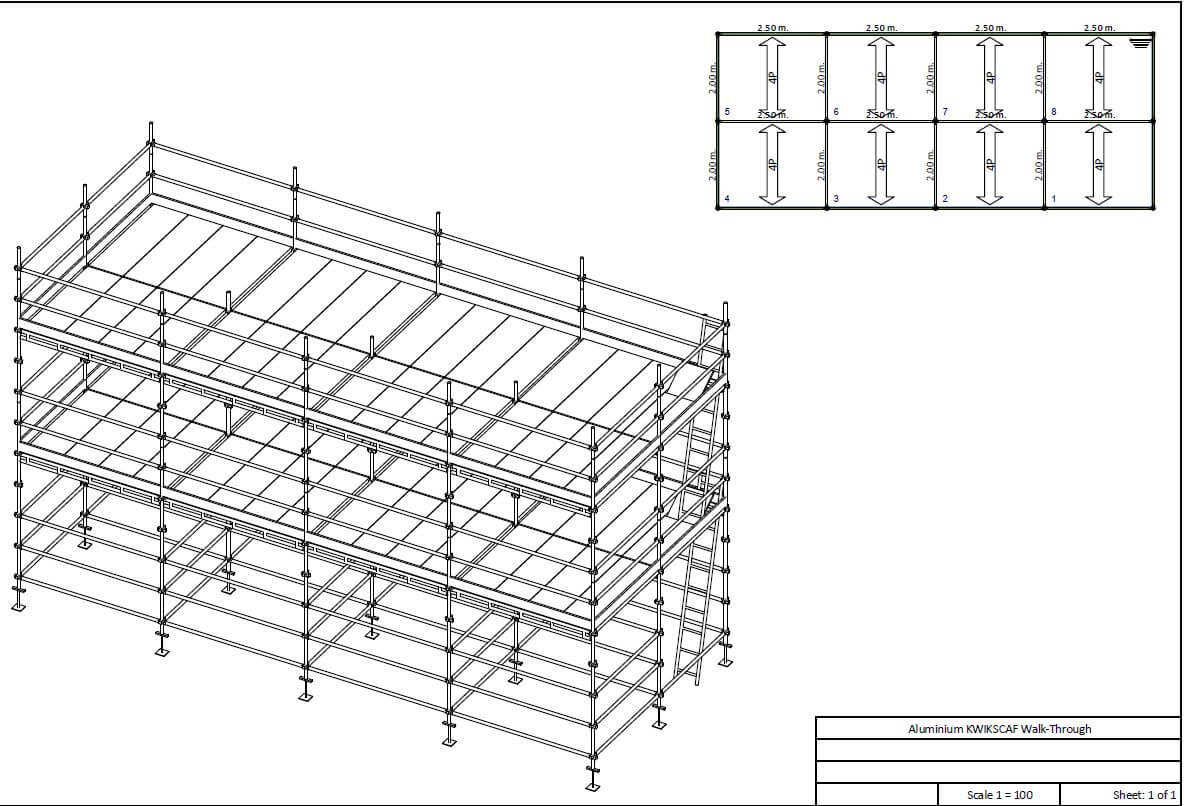

To minimise these risks, this guide requires scaffolders to install and work from fully planked platforms at vertical intervals of between 2 and 3 m (2 m where practicable), and to install guardrails and mid-rails in advance of the decking. There are risks associated with scaffolders falling through and from the scaffold. These concepts should be incorporated into scaffolding manufacturer or supplier information, and erectors’ safe work method statements. The concepts within this guide differ from traditional scaffold erection methods, which are no longer considered acceptable. However, ‘Appendix A – Scaffold design limitations’ only applies to prefabricated steel modular scaffolding. While steel is the dominant material used in the manufacture of prefabricated modular scaffolding, the concepts and procedures in this guide also apply to prefabricated modular scaffolds manufactured from other materials. The purpose of this guide is to provide guidance to the scaffolding industry to safely erect, alter and dismantle prefabricated steel modular scaffolding for commercial and residential buildings.

Following this guide is a means to achieve such compliance. Work health and safety regulations require the control of risk to health and safety. This guide has been developed in consultation with industry and provides practical guidance for those erecting, altering and dismantling scaffolding, and for principal contractors, employers, suppliers of scaffolds and others involved in using prefabricated steel modular scaffolding. Access Guard – Platforms, Scaffolding & Edge Protection.Putlogs are placed at an interval of 1.2 to 1.5 m.There have been a number of incidents where lack of fall prevention systems contributed to worker injuries and there were limited practical solutions to safely erect, alter and dismantle prefabricated steel modular scaffolding. Putlogs are taken out from the hole left in the wall to one end of the ledgers. Ledgers connect the standards at vertical interval of 1.2 to 1.5 m. Distance between the standards is about 2 to 2.5 m. Single scaffolding consists of standards, ledgers, putlogs etc., which is parallel to the wall at a distance of about 1.2 m. Single scaffolding is generally used for brick masonry and is also called as brick layer’s scaffolding.

Types of Scaffolding used in Construction:įollowing are types of Scaffolding in construction: It should be stable and strong to support workmen and other construction material placed on it. Scaffolding is made up of timber or steel. Types of scaffolding varies with the type of construction work. Scaffolding is a temporary structure to support the original structure as well as workmen used it as a platform to carry on the construction works. Types of Scaffolding used in Construction:.

0 kommentar(er)

0 kommentar(er)